BMS 16S 60V 50A Lipo Battery Balance Protection Board

SKU: 1811- Description

- Reviews (0)

Description

Specifications:

Model: 16S 60V/50A same port

Charging current: 40A MAX

Balanced charging function: optional

Overcharge protection voltage: 4.25V

Maximum working current: 50A MAX

Overdischarge protection voltage: 2.6V

Applicable voltage power: 60V <2500W Continuous working maximum current: 40A MAX Temperature protection: With this function. Discharge temperature 75°C; Charging low temperature -7°C Wiring steps: 1. Connect the collection bar to each battery to ensure that the collection bar is effectively connected. Ensure that the wire plug end, a single potential sequence is successively increasing or decreasing. The potential sequence is consistent with that of the socket at the end of the protective plate and the potential is one-to-one correspondence. 2. Weld the B- lead of the protection plate to the total negative B- of the battery string. Ensure that the welding points are solid, reliable, and have good electrical conductivity. Ensure that there are no potential hazards such as extrusion and friction in the cabling position. Ensure that the cabling is smooth and short. Prevent solder, conductive objects or leads from falling into, sticking to or touching the protective plate. 3. Connect the connector of the cable to the socket of the protection board. Weld the B- lead of the protection board to the total negative B- of the battery string. Then, connect the plug of the cable to the socket of the protection board. Ensure that the plug of the cable is properly connected to the socket of the protection board, and that no live objects or leads touch the protection board. 4. B+ and c- are respectively connected to the positive and negative terminals of the charging port. Ensure that during the welding process, do a good job of isolating other leads to avoid short circuit. The battery voltage of discharge interface and charging interface is consistent with the battery voltage, the correctness of polarity and the correctness of connection position. Note: 1. The output power to configure the size of the nickel sheet. 2. Do not let the protection plate touch water, easy to damage. 3. Weld the board, please pay attention to anti-static operation. 4. Not to continuously P+ P- repeated short circuit, there will be a circuit voltage spike, easy to cause damage to MOS tube. Assembly instructions: 1, the battery voltage pairing, the difference is less than 0.1V. 2, the battery's internal resistance pairing, the difference of internal resistance is less than 5 euros. 3, the battery spot welding, test whether the voltage is normal: 4, the board welding nickel pieces. 5. Connect the board to the lithium battery in the order B0 B1 B2 B+. Balancing function: Battery performance deteriorates gradually during use, including the increase of internal resistance, the decrease of capacity, the increase of leakage between electrodes, and the inconsistency of external line loss, which leads to the inconsistency of voltage of each string in the battery pack and the decrease of actual available capacity. In order to alleviate this problem, the equalization function is introduced. In the charging process, when a series of voltage reaches a certain voltage point, start the shunt circuit, reduce the charging current, slow down the charging speed, and wait for other series. So it has a balanced effect.

Be the first to review “BMS 16S 60V 50A Lipo Battery Balance Protection Board”

Most Viewed Products

-

Atmega32u4 Esplora Joystick Game Program Module crystal oscillator Temperature Light Sensor Board

₨2,500.00 -

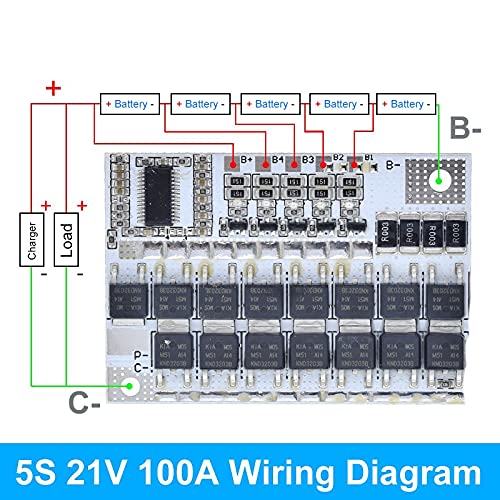

5S BMS 21V 100A Li-ion Battery Protection Circuit Board Balance Charging Module

-

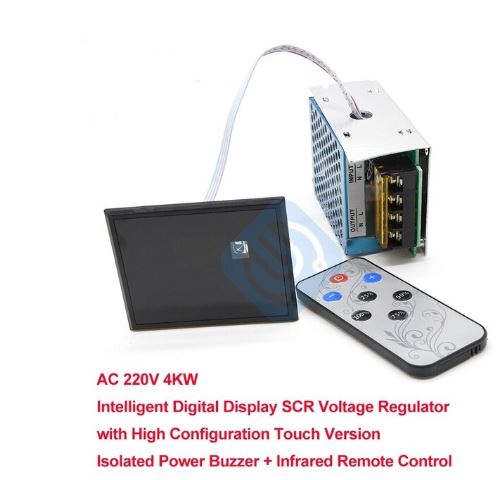

AC PWM 4000W 220V AC SCR Voltage Regulator Dimmer Electric Motor Speed Temperature Controller+Digital Meters For Water Heater Motor

-

Arduino UNO R3 SMD With Cable

Reviews

There are no reviews yet.